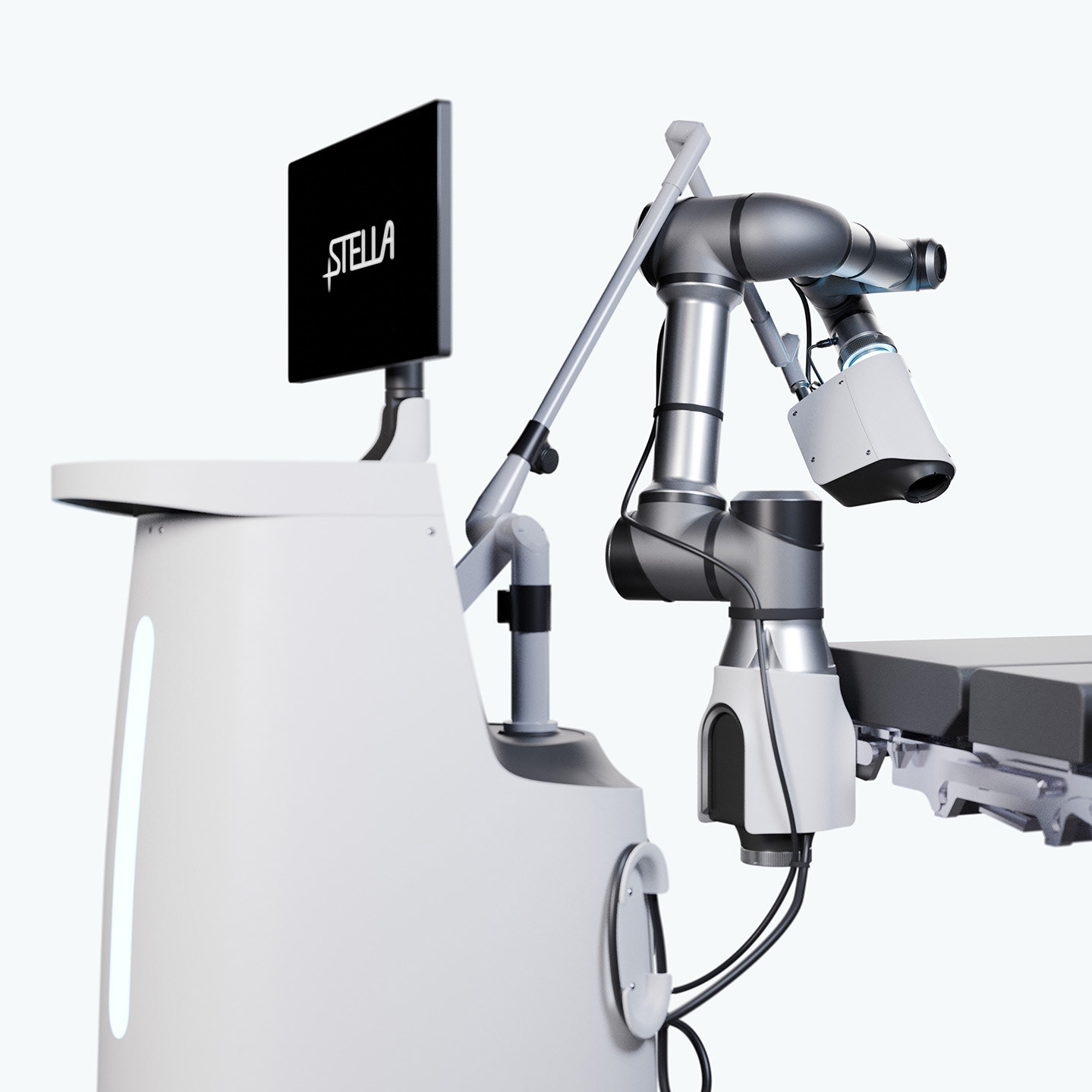

The OrthoJet cart is designed with efficiency and practicality in mind. Its modular height ensures it fits seamlessly into hospital environments without wasting valuable space. Furthermore, different bag inserts can be used to provide more flexibility in the choice of NaCl bag sizes. Additionally, the cart‘s single-mold shell simplifies sterilization, ensuring a high level of hygiene while reducing maintenance effort.

The Orthojet handpiece is the core interaction element of the system, designed for comfortable use over extended periods. A precision nozzle delivers high-pressure NaCl fluid to efficiently remove bone cement. Thanks to its thoughtfully crafted, rotationally symmetric design, the handpiece can be held comfortably in any position. A tactile fin ensures intuitive orientation of the curved nozzle, while an elevated grip geometry allows easy one-handed rotation. A rubberized surface opposite the fin provides a secure, non-slip hold in all conditions. Extensive 3D-printed prototype testing helped optimize the ergonomic design for maximum usability.

A standout feature of the concept is the exceptional versatility of the NaCl bag holder. Designed to accommodate the wide range of bag sizes and systems used in hospitals, its flexible design ensures effortless integration with a variety of models.

As part of Hannover Messe 2025, I had the opportunity to showcase my full-scale 3D-printed prototype at the exhibition booth of Magdeburg-Stendal University of Applied Sciences. Thanks to the life-size 3D print, key ergonomics and usability parameters could once again be tested and validated by visitors at the fair.